Optimising Indoor Drone Inspections in Cement Industry

- Team Volar Alta

- Jun 9, 2022

- 5 min read

Updated: Sep 28, 2024

Inspection in the cement industry has always been an underrepresented topic of discussion. Many challenges come with traditional ways of visual indoor inspections in a cement plant. We, at Volar Alta, want to bring forth these challenges and some interesting facts about this growing industry before we touch on the importance of drones in internal inspections.

With increasing business in sectors such as construction and housing, the cement industry demand in India is expected to reach 419.92 MT per annum by the financial year 2027, according to India Brand Equity Foundation (IBEF).

IBEF, a knowledge system on various sectors, established by the Ministry of Commerce and Industry, also noted that in FY21 cement production increased by 7.8% compared to the previous year. As the demand goes high, the focus on visual inspections is likely to increase too. After all, with the help of these inspections, cement companies ensure preventive maintenance, risk management, employee safety, reduction in downtime, and quality control. These inspections also help cement companies analyze data for future improvements and form new policies.

However, traditional methods of visual inspections in the cement industry come with massive challenges. They put human lives in danger and pose serious health and safety threats.

Challenges with traditional ways of inspections

Assets in a cement plant such as conveyor belts, cyclones, cement silos, clinker silos, clinker coolers, slurry tanks, kilns, air ducts, and storage units come under the category of confined spaces, thus, involving heavy risks and hazards.

Inside a Clinker Silo. Picture credit: SSIC

A worker physically entering a cement kiln, for instance, can be dangerous and challenging. First, there has to be a waiting time for the kiln to cool down, and then scaffolding, ropes, and stick cameras are required making bulk inspections a far-fetched goal. Some areas can also be completely inaccessible to inspectors. In tough situations, the pressure on them to gather visual data is unimaginable. We also cannot overlook the amount of dust in these cement plant assets. It restricts the time a worker can spend inside the asset. The quality of inspection too cannot be guaranteed in some cases.

According to the US Bureau of Labor Statistics, from 2011 to 2018, in seven years, at least 1,030 workers died from occupational injuries involving a confined space. Unfortunately, these are only reported deaths. Due to the increased number of such incidents, different countries have regulations for allowing a permit to enter confined spaces. Getting these permits wastes a lot of time for companies looking for more productive and sustainable solutions.

In addition, manual inspections are also expensive and involve a significant amount of downtime. One of our clients shared with us that reaching the top of the refractory to check if the roof and other connections are safe, required them to fly their inspectors to the top. It costs the client a huge amount of money and time, further delaying the data review process and corrective action planning. Setting up scaffolds in huge indoor assets can be a tedious job in itself requiring crores of rupees and resources.

As the world sees advancements in AI, Robotics, and automation, risking the life of ground employees and wasting resources on scaffolding barely make sense.

How can drones solve these challenges and bring revolution?

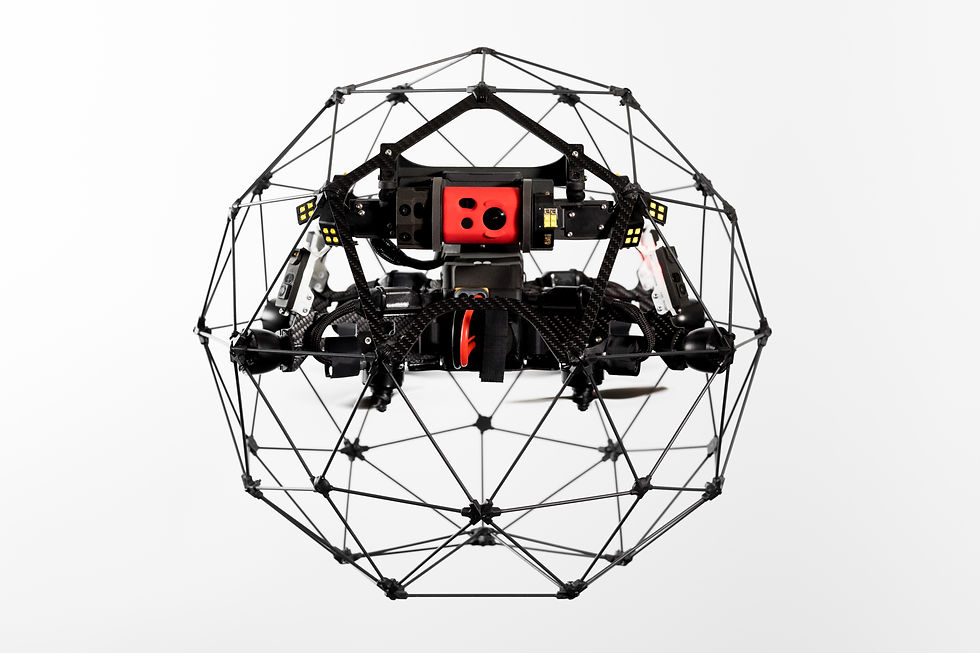

Picture Credits: Flyability

Drone usage by the cement industry completely eradicates the risks to human life and improves safety. It gives companies a huge competitive advantage because of fascinating results such as accurate and elaborate data capture, actionable insights, and reduced downtime on account of increased frequency of inspections and more coverage - all this, while improving employee health and safety multi-folds.

Like other industries, here is a chance for cement plants to leverage advanced indoor drones like Elios 2, automation, AI, robotics, and more. Following are the top benefits of using drones to internally inspect the cement plant:

1. Ensure safety and health of ground workers

Picture Credits: Flyability

All companies today want to practice ethics and sustainability. Improving the safety of employees has been an important goal for all great industry leaders. With indoor drone inspections by Volar Alta, cement companies can achieve exactly that and much more. Our services ensure the safety of ground workers or inspectors in cement plants.

Existing manual inspectors can be deployed for other important work by the companies. They can analyze the rich data received from drones and improve the overall safety of the inspection. They can be trained to study the data and find deficiencies for quick and timely maintenance and corrective actions.

Further, inspectors can enter confined spaces only to do maintenance-related jobs after analyzing drone data. The drone footage will make their tasks faster and more precise.

2. Increase the frequency of inspections

Drones inspections are faster than manual indoor inspections by a huge margin. The number of hours that a ground worker can spend in an asset is limited, but drones don’t have such limitations. They can stay inside an asset for longer and yet inspect the next asset consecutively without long waiting hours. Drones also save the time taken for fixing scaffolds inside the assets and arranging head mounts, cameras, or ropes.

3. Reduce cost and downtime

A major cement manufacturer company’s Digital Transformation Head shared that Volar Alta’s internal drone equipment services helped them cut scheduled maintenance downtime by 4 days while saving Rs. 2 Cr in scaffolding costs.

Different kinds of scaffolding, head-camera, gears, PPEs, ropes, etc cost companies crores. Volar Alta’s internal drone inspection services for the cement industry help you save this cost and enhance operations. We not only conduct inspections for you but also create insightful reports that can be analyzed for improvements and maintenance.

4. Accurate visual data

Even in extreme conditions, and high-dust indoor areas, drones deployed by Volar Alta provide impressive image resolutions. The drones give excellent visibility in zero-lumen conditions. 3D model surveys can be created using the footage.

Check the video here:

5. Advance data collection and analysis

Drones allow better control in data capture than CCTV or other robotic solutions. Once the top quality data is created, our data analysis team prepares detailed reports documenting all findings and helps you catch anomalies and faults immediately.

These reports can be used for maintenance, corrective action, policy change, risk assessment, and much more.

6. Increased productivity in daily operations

Drones help companies go fully digital with inspection - a goal that more and more leaders have been expressing in the past few years. Volar Alta helps such companies optimize new-age technology in the most efficient and reliable ways. Internal drone inspection opens new doors and opportunities for both service providers and cement companies.

Drones are not just for hobbyists anymore. Drones can bring a revolution to industries such as cement which require inspections of inaccessible confined spaces. Using some best practices and tips, drone pilots can make the most of one single flight and help companies gather data, do maintenance, fix issues, reduce costs and increase productivity. Companies looking for fast digital transformation should wait no further and adopt this technology to give a competitive advantage to competitors.

We, at Volar Alta, are helping some of the major cement companies. To know more about our services and get case studies, contact us at niharika@volaralta.com.

Comments