The Future of Drone-Based Inspections in Heavy Industries: Key Trends to Watch

- Team Volar Alta

- Oct 2, 2023

- 3 min read

Updated: Feb 2, 2024

In heavy and process industries, safety, efficiency, and precision is paramount. In this context, drone-based inspections have emerged as transformative tools for monitoring critical infrastructure, both in external and confined spaces. As we look forward, several emerging trends in the drone industry are poised to revolutionize the landscape of industrial inspections within these sectors.

Let's delve into these trends, which promise to shape the future of inspections in heavy industries.

1. 5G Connectivity: Powering Real-Time Insights

The integration of 5G connectivity is set to be a game-changer for drone-based inspections in heavy industries. With 5G networks, drones can transmit data in real-time, offering low latency and high-speed connections. This capability is especially crucial when inspecting large industrial facilities like oil refineries or power plants, providing real-time insights to operators, enhancing safety, and enabling immediate decision-making.

With drones, the goal is to allow operators to see and react to things in real-time. For instance, if a drone is flying at 25 mph, a 100-millisecond delay means the drone has travelled about three feet before the operator sees the video. Three feet could easily be the difference between an accomplished and failed task or a successful flight and a crash.

A connection to a 5G network enables a drone to send information back to the base in real-time. Early drone technology meant all the data from drone-mounted cameras, sensors and telemetry could only be uploaded from the drone’s hard drive once it had landed. A 5G connection changes that to real-time and opens a whole new world of possibilities. The existing 4G networks have an average latency of approximately 50 milliseconds. 5G networks, on the upper hand, should clock in around 10 milliseconds.

2. Autonomous Drones: Smart and Independent Inspectors

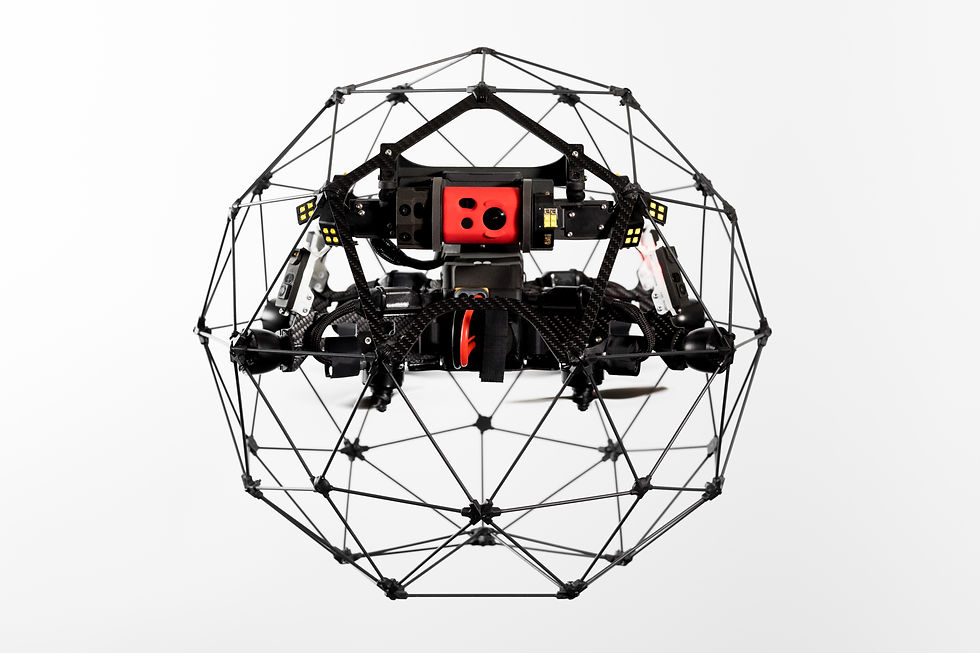

Autonomous drones, equipped with advanced navigation systems and artificial intelligence (AI), are on the rise. These drones can autonomously navigate complex environments, follow predefined inspection routes, and make real-time decisions. This autonomy not only reduces human intervention but also enhances safety and efficiency in confined spaces and external inspections within heavy industries.

3. Advanced Sensor Technologies: Precision in Every Detail

Sensor technologies have advanced significantly, providing drones with an array of options tailored to heavy industries. LiDAR (Light Detection and Ranging) sensors enable detailed 3D mapping, while multispectral and hyperspectral sensors are invaluable for inspecting chemical facilities or power plants. These sensors offer unparalleled precision, enhancing the quality of data collected. The growing applications of drone sensors in the industrial sector are predicted to fortify the growth of the global drone sensors market in the approaching years. The market generated a revenue of $3,930.4 million in 2022 and is expected to grow at a striking CAGR of 23.2% from 2022 to 2031.

4. Artificial Intelligence (AI) and Machine Learning (ML): Data Analysis Powerhouses

AI and ML algorithms are becoming indispensable in drone-based inspections within heavy industries. They enable drones to analyse massive datasets swiftly and accurately, identifying anomalies, defects, or areas of concern. Whether it is detecting corrosion in oil & gas pipelines or assessing the structural integrity of cement silos, or in industries like mining, energy transmission, construction, military, and security, AI-powered analysis elevates inspection accuracy.

5. Beyond Visual Line of Sight (BVLOS) Operations: Expanding Reach

Advancements in regulations are opening opportunities for Beyond Visual Line of Sight (BVLOS) operations within heavy industries. BVLOS allows drones to cover larger areas, making them ideal for inspecting extensive infrastructure like chemical processing plants, power transmission lines, and oil & gas pipelines. This trend is set to revolutionize the scalability and reach of drone-based inspections.

6. Environmental Sustainability: Greener Inspections

In line with global sustainability efforts, the drone industry is moving towards greener solutions. Electric drones, powered by renewable energy sources, reduce carbon emissions, making inspections more environmentally friendly. This shift aligns with the sustainability goals of heavy industries that prioritize environmental responsibility.

7. Enhanced Security Measures: Protecting Data and Operations

With the growing adoption of drones, ensuring data security and operational safety is of utmost importance within heavy industries. Emerging trends in encryption, authentication, and cybersecurity solutions play a pivotal role in safeguarding sensitive data and protecting drones from unauthorized access and interference, ensuring the integrity of inspections.

Embracing a Transformative Future in Heavy Industries

The future of drone-based inspections in heavy industries is marked by innovation and transformation. These trends, from 5G connectivity to AI-powered analysis and BVLOS operations, promise to enhance the efficiency, precision, and scope of industrial inspections. Drones are set to play an increasingly central role in ensuring the safety, reliability, and sustainability of critical infrastructure within heavy industries. Stay tuned as we help embark more and more companies on this exciting journey into the future of Industrial Inspections.

Comments